Relaxation within the interface between the nut and bolt threads and relaxation of the stressed concrete in the areas adjacent to the expansion wedges contribute to this decrease. When a torque controlled expansion anchor is installed in uncracked concrete, the anchor pre-load created by torquing will decrease over time.

Hilti profis installation error cracked#

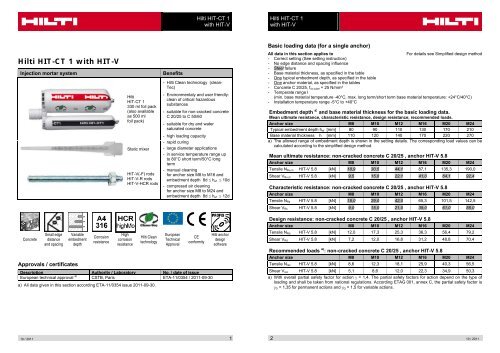

It is necessary to make a distinction between anchor performance in uncracked concrete versus cracked concrete. Effects of external tension load without clamping. Figure 3 illustrates the effect an external tension load has on a torque-controlled expansion anchor after the clamping load between the fixture and concrete has been removed.įigure 3. Once the clamping load between the fixture and concrete is completely removed, any external tension load applied to the fixture acts directly on the anchor. Since concrete is typically stiffer in compression compared to the tension stiffness of an anchor, the additional tension load on the anchor resulting from the external tension load is minimized as long as any clamping load remains. The amount of pre-load, clamping, and displacement are dependent on the parameters listed above.Īpplication of external tension load to the fixture reduces the clamping load between the fixture and concrete while adding some tension load to the anchor. compression) displacement in the concrete. tension) displacement, which is offset by a negative (i.e. Torquing causes the anchor to undergo a positive (i.e. The load corresponding to pre-load in the anchor, and clamping between the fixture and the concrete, is designated N torque. Effects of external tension load with clamping.

the friction between the fixture and concrete surface.

Clamping eliminates gaps between the fixture and concrete. Pre-loading also reduces anchor fatigue under cyclic loads. Pre-loading reduces the amount of displacement the anchor undergoes when subjected to external tension load. When the wedges are expanded, a tension pre-load develops in the anchor along with a compression clamping load between the fixture and the concrete. The tapered mandrel can be a part of the bolt shank (Figure 1a), or it can be a separate assembly that threads onto the bolt shank (Figure 1b). This mechanism consists of a tapered mandrel that moves up through the wedges. Applying a torque to the nut activates a mechanism whereby displacement (movement) causes the wedges to expand into the concrete. Why Torque Expansion Anchors?įigure 1 illustrates the components of a torque-controlled expansion anchor. a) Hilti Kwik Bolt-TZ Anchor b) Hilti HSL-3 Anchor.

0 kommentar(er)

0 kommentar(er)